The functional principle - genious and simple.

Modern drives are often equipped with rotary encoders. For the operator, a detailed inspection is made difficult due to the large diversity of encoders in the market. This applies in particular for repairers of electric motors but also for analyses in production. An extensive inspection without special measuring technology is not possible.

The EncoderAnalyzer offers valuable services by simplifying the encoder inspection as it supplies the encoder with voltage and measures all signals. Afterwards they are automatically evaluated. The result is indicated either as a clear GO (o.k. ) or a clear NOGO (not o.k.).

The following rotary encoders and sensor systems may be inspected:

- Incremental square wave encoders with A, /A, B, /B, N, /N, U, /U, V, /V, W, /W6-channel EncoderAnalyzer

-

Sine-cosine encoders with sin, /sin, cos, /cos, N, /N

-

Hall elements with A, /A, B, /B, N, /N

-

Hall elements with U, /U, V, /V, W, /W

-

Commutation signals / block commutation

-

Multiturn-absolute encoders with SSi- and Hiperface-interface

-

optional resolvers

-

optional 3-phase motor current measurment during operation

-

optional EMF-voltage measurement up to 700V

-

optional resolver adjustment regarding the moto´s EMF

-

optional programming the rotary encoder´s angle offset

The functional principle.

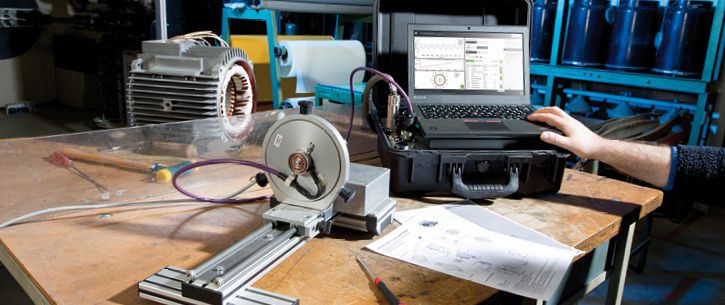

The EncoderAnalyzer consists of two components: The measuring module and the analysing software, which is to be installed on a PC.

The measuring module provides a connection for the encoders to be inspected. Furthermore, additional components for supplementary measuring functions may be connected to the measuring module.

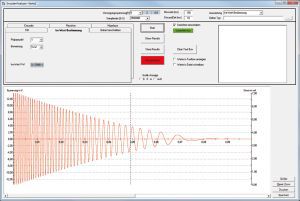

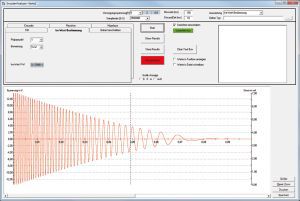

The measuring module performs the tests. For this, it determines millions of measuring values during one revolution and transfers them to a PC. The communication between measuring module and PC is done by a Gigabit-Ethernet connection. By means of the analyzing software the measured results are automatically evaluated. At the end of an inspection the software presents the result on the screen. For a better understanding, errors detected at a broken rotary encoder, are graphically displayed like in an oscilloscope.

The test results are stored in a database. If requested, a detailed test report may be printed.

Connecting the rotary encoder

The rotary encoder to be inspected is connected with the measuring module by a measuring lead. On the measuring module´s front side up to 2 measuring sockets are available for the connection of the measuring leads. verbunden. The number of measuring sockets depends on the ordered options. The EncoderAnalyzer with all 12 measuring channels is equipped with 2 measuring sockets.

A voltage supply of 3...30 V is also integrated in the EncoderAnalyzer. Depending on the encoder, voltage level and maximum permissible power consumption are entered by the operator via software input. During the measurement the EncoderAnalyzer monitors the power consumption. In case the maximum permissible value is exceeded, the voltage supply is automatically switched off.

- Measuring socket MU for

- three high-voltage measuring inputs

- Measuring socket MI for

- three current measuring inputs for current clamps

- Measuring socket ME for

- Incremental square-wave encoders

- Sine-cosine encoders

- Hall elements

- Commutation signals/ Block commutation

- Encoder´s voltage supply

- Communication - and programming interface

The analysis software

The fast and intelligent measuring technology and the user-friendly, intuitive analysis software are perfectly matched with each other. Only a few settings and selections are sufficient, to configure the measurement for the encoder to be tested.

The extensive evaluations lead to clear and easy-understandable results. Special or detailed knowhow is not necessary while dealing with the analysis software. The software helps and supports during the connection and evaluation of encoders.

As supplement to the encoder analysis the software also assists during the angle adjustment of rotary encoders. No matter, if the rotary encoder needs to be adjusted by mechanical turning or if only the angle offset needs to be determined, the software graphically supports the operator during the adjustment. Depending on the encoder type and the EncoderAnalyzer´s equipment, the offset angle may also be written in the rotary encoder.

EMF-measurment Resolver signal

Measuring principles for the encoder inspection

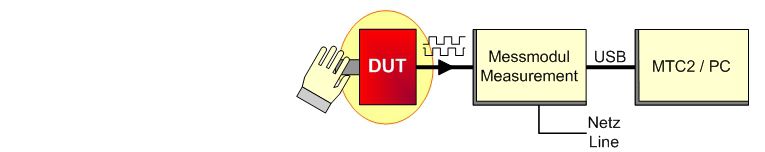

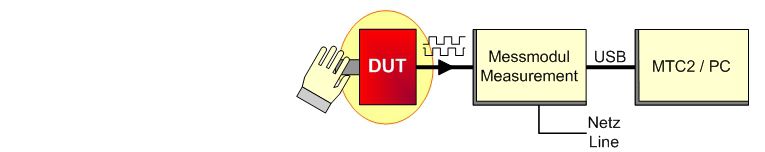

1. Rotary encoder- / Resolver test

The rotary encoder is connected with the measuring module with an appropriate connection lead. Afterwards you manually turn the encoder´s axis. The arising impulses are digitized and evaluated by the measuring module.

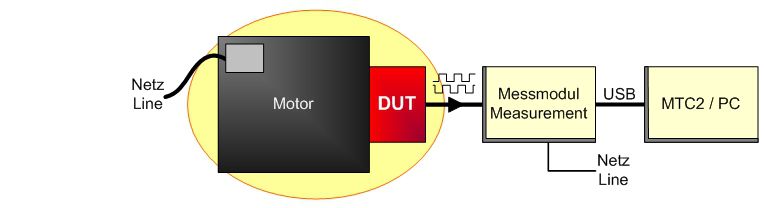

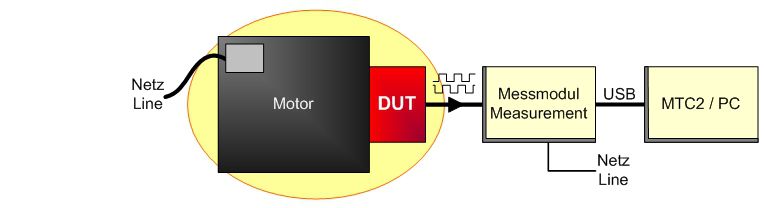

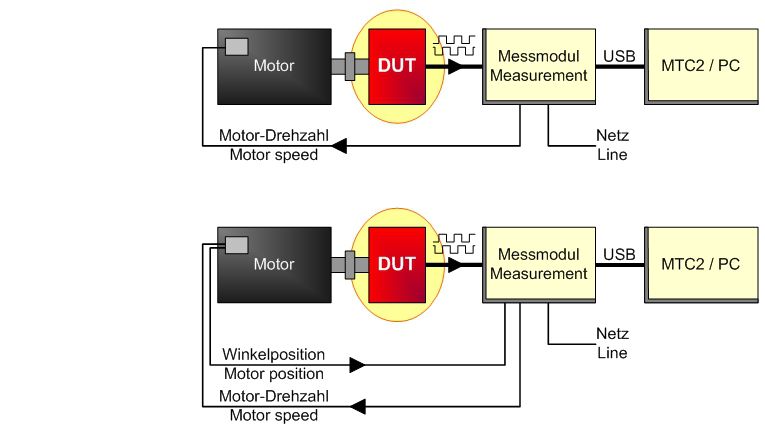

2. Rotary encoder- / Resolver test together with the motor

The rotary encoder mounted on the motor is connected with the measuring module with an appropriate connection lead. Afterwards the motor is directly operated from the mains or via a frequency converter. The arising impulses are digitized and evaluated by the measuring module.

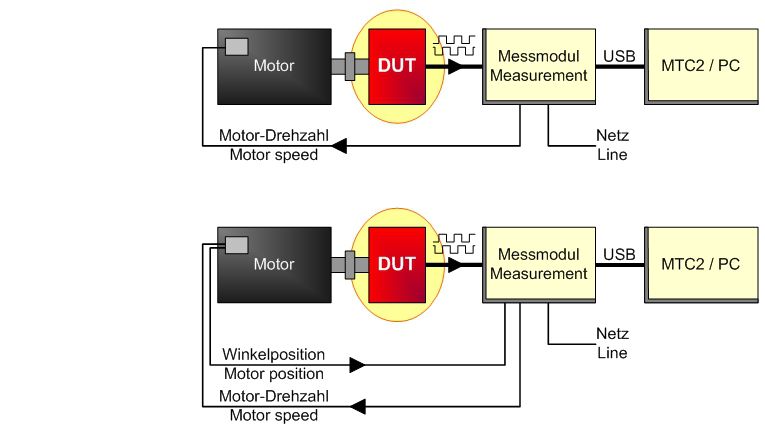

3. Rotary encoder- / Resolver test by means of a test installation

In a special SCHLEICH-test installation the rotary encoder is mechanically coupled with a small drive motor. Via an appropriate connection lead it is connected with the measuring module. For testing purposes the module actuates the drive motor. The arising impulses are digitized and evaluated by the measuring module. Depending on the encoder to be tested the motor´s angle position may also be determined.

4. Resolver- / Hall element adjustment

For the adjustment the resolver, which is still connected with the motor, is additionally connected with the measuring module via an appropriate connection lead. Furthermore the motor is mechanically coupled by a drive motor. Afterwards the drive motor is directly operated from the mains or, better, by a frequency converter. The arising pulses and the Back-EMF induced in the windings are digitized and evaluated by the measuring module. The measuring module derives the adjustment-information from the measured values which is also indicated on the screen.

Voltage supply for the encoder

For testing purposes, the encoder has to be supplied with DC-voltage which is generated in the measuring module and in the requested voltage level. The supply voltage is shortcircuit proof and the encoder´s power consumption is also inspected. In case the power consumption is too high, the measuring module automatically switches-off the supply voltage due to safety reasons.

Database

The software is equipped with a database with storage capacity for thousands of encoders and resolver.

For the inspection of an encoder, the corresponding data has to be contained in the database. The data consists of relevant information as e.g. the encoder type, the supply voltage level, the pin assignment and so on. Based on this information, the software assists you regarding the suitable connection cable and how to properly connect the encoder.

Furthermore the database contains even more information. Although they are not important for the measurements, they inform about further details of the encoder.