MTC2

Universal winding testers — Surge voltage test 6, 12, 15, 25, 30, 40 or 50 KV

Key-Facts

Winding tests in its purest form.

- Inspection of motors and generators up to 500 MW

- Surge voltage up to 50 KV

- Surge energy 125 Joule

- High surge current 2000 A

- Fastest rise time 60 ns

- Fully-integrated partial discharge test according to IEC 61934 and DIN EN 60034-18-41

- Resistance measurement in 4-wire technology with temperature compensation

- Insulation resistance test with automatic PI-measurement

- Inductance test| LCR-inductance test bridge

- Integrated armature test assistant, armature adapter and armature booster

- 4 winding connections (windings + neutral point) plus frame connection

- A number of tests can be performed without the necessity to reconnect connection leads

- Easy and manual inspection without parameterization

- Automatic test with subsequent Go/ NoGo - comparison

- Result recording with test object-related data

- Printing with any Windows-printers plus PDF

- Data base for numerous test sequences and test results

- Integrated high-quality industrial-PC with Windows®

- Full network connectivity

- Intuitive operation via touchscreen, mouse and keyboard

- Possibility for remote maintenance or remote calibration

- Remote control option for automation

- Perfect for OEMs

Description

Intuition – Function – Perfection.

The MTC2 is our premium surge voltage tester - no other tester offers such a diversity of features. With the MTC2 you inspect coils, stators, armatures and all kinds of windings according to the latest state of the art - uncompromising and precise.

Innovations, technology lead and a patented analytical method for surge voltage characterize the MTC2-surge voltage testers of the 6th generation.

A finely graduated variety of testers from 6 KV up to 50 KV is available.

Based on 25 years experience, extensive know-how and consistent optimization you get THE "state-of-the-art surge voltage tester".

What makes the MTC2 so special?

4 connection leads

4 connectionleads offer the possibility to contact all relevant winding connections at the same time. The 3 phase connections and the neutral point are connected to the 4 connection leads. In this way it is possible to achive a unique test accuracy.

Automatic test method switch-over

As soon as the test object is connected, the MTC2 automatically measures at all 4 connections. Thanks to the integrated test method switchover, there´s no need for manual re-clamping. This saves time and avoids mistakes.

The surge voltage test with standard-compliant rise time leaves no defect undetected. Modern, automatic evaluations facilitate the fault analysis.

Optional partial discharge test with surge voltage

The innovative, standard-compliant partial discharge test can easily be integrated. It gives you information about critical insulation weaknesses and the suitability for operation with frequency converters. SCHLEICH pursues two strategies to obtain good test results at stators as well as at entirely-assembled motors: Measurement via coupler in the measuring lead (perfect for motors) and measurement via antenna (perfect for stators).

Optional precise resistance measurement in 4-wire-technology

To achieve precise measuring results by comparing the three phases´resistances , the resistance is measured in 4-wire technology. Of course, the 4-wire technolgy is also applied by means of the automatic test method switchover!

Optional high-voltage test with AC

In addition, you can also perform a high-voltage test with AC. Of course, the automatic test method switchover is also applicable in this case.

The measuring technology allows you to find faults in rotors or stators and to detect broken bars in the squirrel-cage rotor.

Applications

Motor repair | Manual stator inspection

The MTC2 is immediately ready to perform spontaneous measurements. By means of the unique manual mode all test methods (resistance-, surge voltage,- insulation resistance- and partial discharge test) may be started. There´s no need for test parameterizations in advance. You only enter the requested test voltage and start the test.

The software always provides you, similar to a multimeter, with the current test results. Thus, the evaluation of the winding and its´insulating system is instantly possible and you are able to decide if the motor needs a repair and what needs to be repaired.

In addition, a variety of motor data can be entered, which can also be printed, together with the test results, on the SCHLEICH standard test report.

Motor repair | Manual inspection of squirrel cage rotors or stators

By means of special test probes a turn-to-turn fault in the stator is determined. This procedure may also be applied at squirrel cage rotors.

![]() See also : Rotor-Stator-Check

See also : Rotor-Stator-Check

Motor repair| Manual rotor inspection

By means of special test probes and the armature booster the rotor is inspected from bar to bar. Usually it is tested between two adjacent bars. A quadrant- or semicircle measurements also possible. The operator is led through the test by the integrated armature booster software.

In this case the armature booster is used for direct measurements at a train.

![]() See also: Armature booster in SchleichPedia

See also: Armature booster in SchleichPedia

Motor repair| Fully-automatic inspection

In the repair sector, a great variety of motors and generators may be fully-automatic inspected.

For this, the MTC2 offers a fully-automatic mode, which is perfectly-suited for use the in electrical engineering industry. There are 3 options to use it:

First option

As standard, the MTC2 is already equipped with a great number of test sequences for any arbitrary nominal voltage classes. Those are already pre-set for the different test tasks and may not be adjusted. Thanks to this, you can immediately start, even in the fully-automatic mode. The operator only has to select the test sequence according to the motor´s nominal voltage and connect the motor or stator. Then he can start the fully-automatic test with automatic Go/ NoGo evaluation.

Es ist kein technisch geschultes Personal notwendig, um die Messwerte korrekt zu beurteilen!

Second option

In the fully-automatic mode the test is performed according to a freely-definable test sequence. The tester evaluates the measuring results fully-automatically and displays them either in red (NoGo) or in green colour (GO) on the screen. There´s no need for special trained or skilled staff to properly evaluate the measured results.

A nearly unlimited number of test sequences may be entered, which may be ideally adapted to and optimized for your test situation and tasks.

Third option

All saved tests may be accessed at any time and further measurements based on these settings may be performed. By this you get a direct comparison to former test results.

Motor production

The MTC2 may be easily integrated in your production line. The cabinet´s dimensions are based on a 19"-housing in which the tester may perfectly be integrated. Additional interfaces allow an entire remote-control by the master PC.

For different kids of test objects any arbitrary number of test sequences may be saved in the MTC2 and accessed and started via the interface.

All test results are accessible via the interface and may be stored in a central data base by means of the master PC. Furthermore it´s possible to save the results either locally on the tester or directly in the network.

Further impressions

|

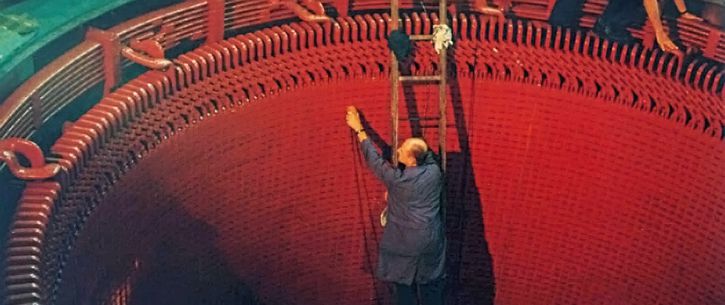

MTC2 on its way to the scene

|

|

Motor inspection with the portable MTC2

|

|

Inspection of a broken winding

|

|

Inspection of DC motors

|

|

Testing without limits

|

Technology

Benefits at a glance.

Voltage supply

- Voltage range 90-250 V, 47-63Hz

- key switch for unlocking

Connections

- 4 + laminated core (ground)

Autotest

- automatic stator-, motor inspection

- fully-automatic fault analysis

Surge voltage

- 6, 12, 15, 25, 30, 40 and 50 KV

- Rise time100-200ns according to IEEE Std 522-2004 (dependent from test object)

- automatic and manual surge voltage test

- 1-, 2- and 3-phase

- automatic evaluation

- 8 different evaluation methods incl. correlation (patented by SCHLEICH)

- optional armature booster to inspect DC armatures

High-voltage DC

- 6, 12, 15, 25, 30, 40 and 50 KV

- manually adjustable

- automatically programmable

- step voltage measurement

Insulation resistance DC

- 6, 12, 15, 25, 30, 40 and 50 KV

- according to VDE 0701

- 1 MΩ-100 GΩ

Polarization index

- 6, 12, 15, 25, 30, 40 and 50 KV

- PI-measurement

- DAR-measurement

- automatic measurement

Partial discharge Surge - Option

- 6, 12, 15 and 25 KV

- according to DIN EN 60034-18:2014

- Measurements of

- PDIV - Partial discharge inception voltage

- RPDIV - Repetitive partial discharge inception voltage

- RPDEV - Repetitive partial discharge extinction voltage

- PDEV - Partial discharge extinction voltage

- Measurements via coupler in the test lead- perfect for motors

- Measurements via antenna - perfect for stators

Resistance- Option

- 1, 2 and 3-phase

- 1 mΩ-100 kΩ

- imbalance inspection

- 4-wire technology

- ambient temperature compensation

High-voltage AC - Option

- up to 6 KV, 100 mA

- 1, 2 and 3-phase

⇒ More details available under Download.

Accessories

For further information please contact our technical sales also contact us by phone