Excellent quality for your product.

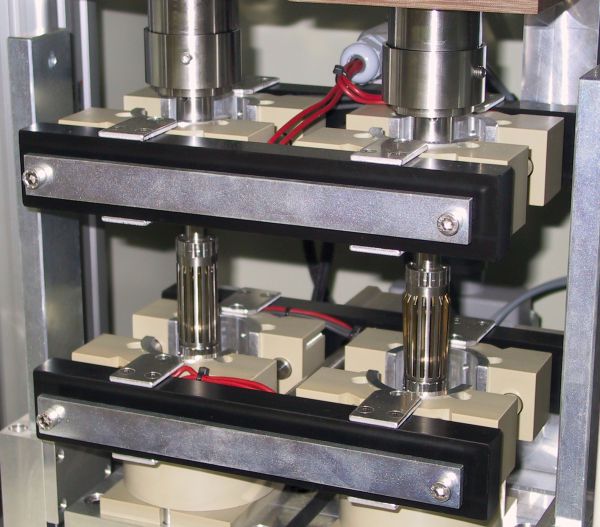

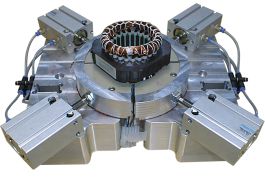

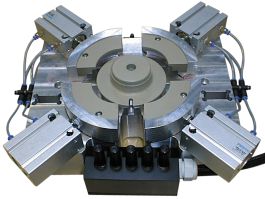

SCHLEICH-bonding machines make it possible to bond and test self-bonding wired coils directly after the winding process. They allow the bonding and curing of coils for single- and three phase motors and all kinds of armatures and coils like speaker coils, magnet coils etc.

The bonding process is monitored by a PC and is performed by means of the controlled, electrical heating of the coils. Depending on the current density, different heating times result. Different current densities lead to bonding processes which may last from only a few seconds up to several minutes. After the heating phase it is also possible to constantly keep the reached temperature for a certain time. The result is a uniform temperature distribution within the winding and thus the best possible, homogeneous bonding in all parts of the winding.

Besides the use at single working stations our bonding machines are also perfectly suitable for the integration into fully-automatic production lines. Pallet control in a production line or the exchange of data with a PLC can also be easily realized. The machine´s design is intended to control up to eight independently running bonding processes and to display them on the screen.

As system supplier we are able, in addition to the electric bonding machine itself, to also provide the entire mechanics which may consist of single bonding stations, a rotary indexing table or even an entire production line. Only the combination of these perfectly-matched components assures you the best possible production result.

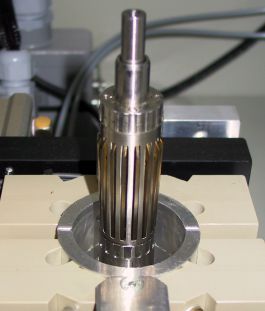

Of course, also overhang forming tools and expanding mandrels belong to our range of products.

Furthermore our bonding machines may be extended by our MTC3- stator testers which make it possible to get detailed information about your product´s quality before and after the bonding process.

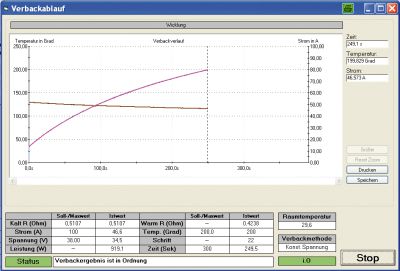

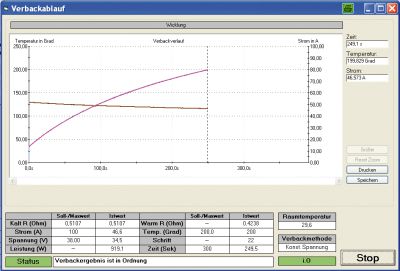

Bonding variant: Constant voltage method

A constant voltage is supplied to the winding. With increasing temperature also the winding´s resistance increases and thus the current decreases. Consequently, with rising temperature less power/energy is transferred into the winding.

The advantage of this method is, that the temperature rises rather slow which results in a good and even stator heating. Thus, the temperature deviation between overhang and slot is ideally low when reaching the bonding temperature.

However, as the densest current in the wire can only be reached at the beginning of the bonding process, no short bonding time is possible.

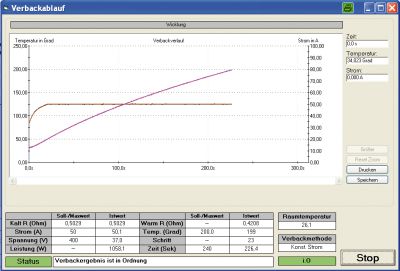

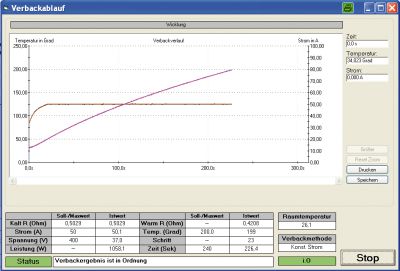

Bonding variant: Constant current method

This method keeps a constant current level during the bonding process. To be able to keep the decreasing current level constant while the resistance increases, the bonding machine automatically increases the voltage during the bonding process. That is why the final temperature is reached in shorter time compared to the bonding method with constant voltage. However, at this, the temperature may be unevenly distributed in the winding.

The advantage of this method is the achievement of short bonding times. However, in most cases an uneven temperature distribution occurs.

Bonding variant: Constant temperature method

During the constant-voltage or constant-current method the bonding process is stopped, as soon as the bonding temperature is reached.

The time, in which the self bonding coat melts at the wire´s surface and coalescenses with the neighbouring strands is relatively short at both methods. Due to this, it may happen, that the slot´s wires stay a bit cooler then the ones in the overhang, due to the surrounding laminated core. This could lead to a poorer quality.

With the constant-temperature method, as soon as the targeted temperature is reached, it is kept for a certain time. By this, the time in which the self bonding coat melts at the wire´s surface and coalescenses with the neighbouring strands, is extended.

Bonding method: Temperature profile method

Bonding with a temperature profile basically corresponds to bonding with constant temperature, but, however, at this method, several temperature levels are reached one after another.

At this, the temperature difference between hangover and slot may aready be adapted during lower pre-temperatures before the actual melting process.

This method is mainly used in cases, where the laminated core is rather long (compared to a relatively short hangover) and/ or if the laminated core´s dimensions are rather large.