The universal tool.

The MotorAnalyzer1 is an all-purpose tester for testing electric motors and windings. It combines ten different test methods in a user-friendly and mobile tester. The combination of test methods, the compact design and the option for a battery operation turn the MotorAnalyzer1 into an ideal tool for the on-site-operation - especially at difficult operation locations.

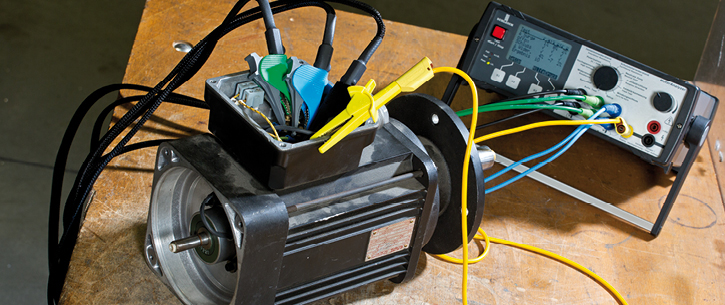

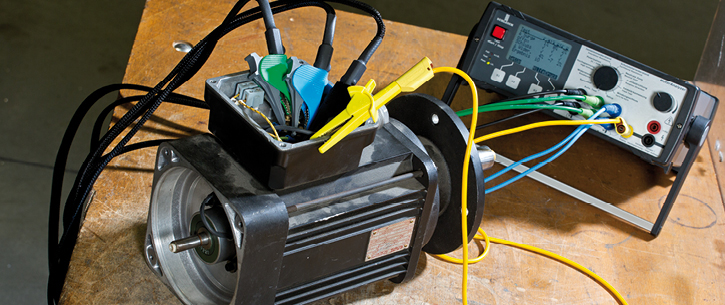

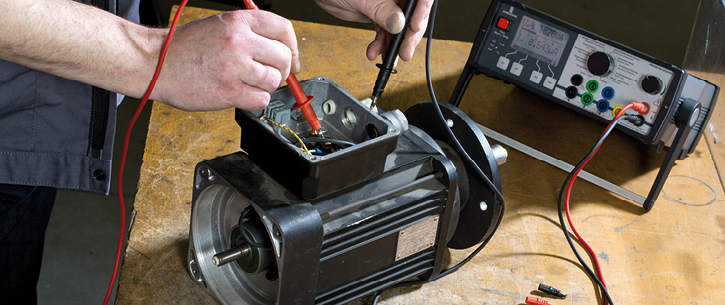

To inspect a three-phase current motor the three winding connections as well as the motor cabinet are connected with the tester. The MotorAnalyzer1 inspects the motor by automatically running a surge and resistance test. Furthermore a high-voltage test is performed in order to quickly evaluate the motor´s quality.

The MotorAnalyzer1 is ideally suited for applications within the production or for mobile operation on-site. Even under difficult circumstances (e.g. when hanging on a crane) electric motors may be ideally inspected by the mains-independent battery-operation. The MotorAnalyzer1 enabales the operator to make a clear go/ no go decision. For this numerous test methods and modern software analyses with optimum graphical display are available.

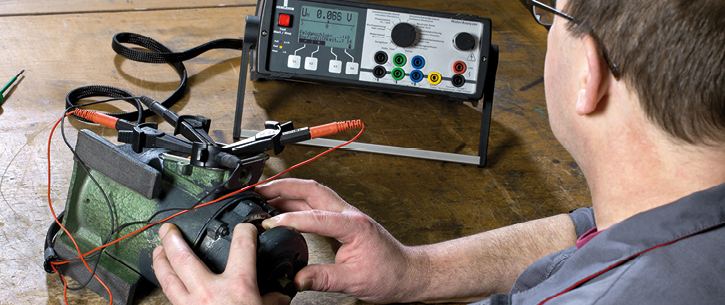

Motor test in workshops.

A useful measuring feature is the autotest. With it, you receive all test results at a glance by only one single fully-automatic test run.

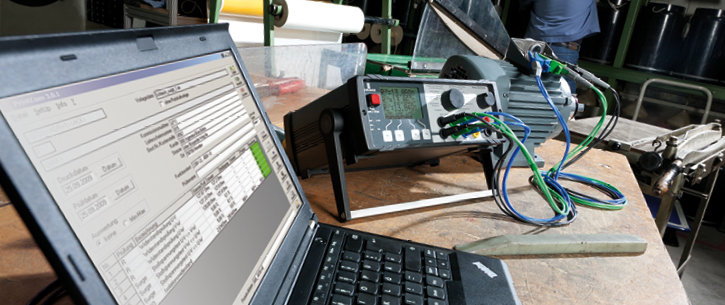

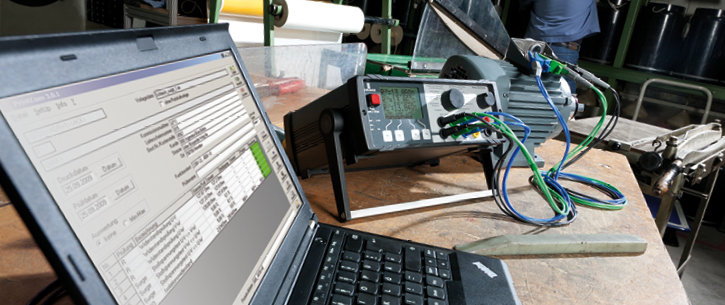

Inspection of a motor and test results transfer to a PC, where they are saved and printed.

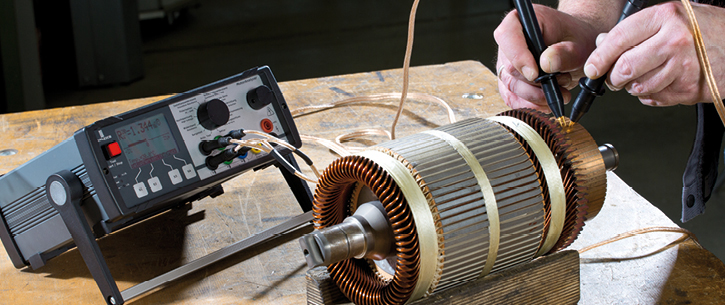

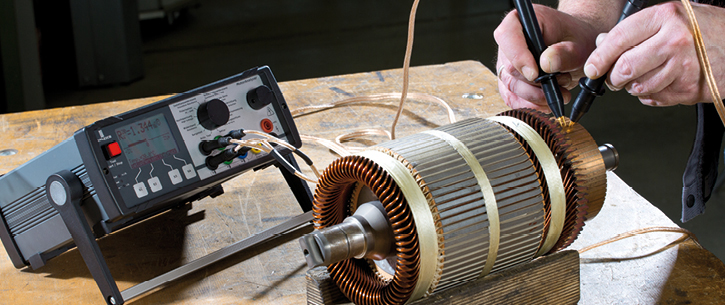

Where is the turn-to-turn fault?

Detection of a turn-to-turn fault. Each slot is inspected by the test probe.

In case of a turn-to-turn fault, there has to be a deviation in two slots, as the faulty coil leads through them.

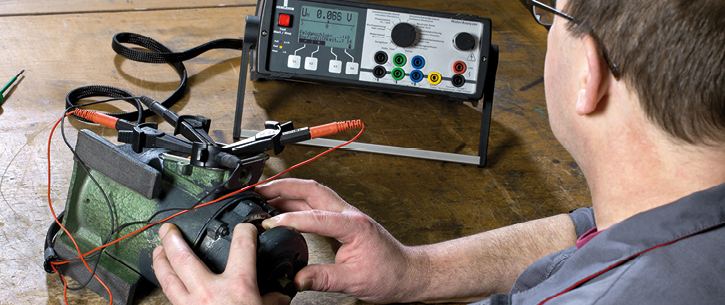

Turn-to-turn fault inspection at a rotor

Resistance test at Rotors

Resistance measurement by means of two 4-wire test probes. Each test probe´s two measuring contacts are contacted to a bar. The determination of the single resistances is done by measuring the entire collector, from bar to bar.

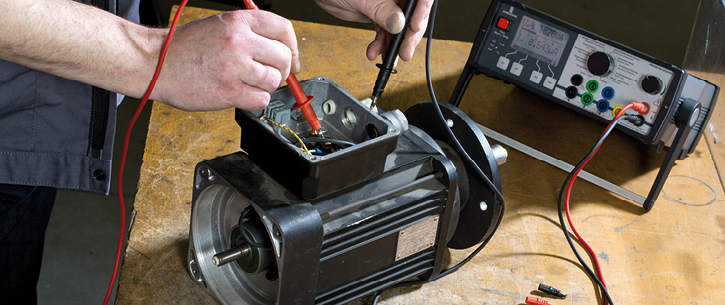

High-voltage test with DC.

High-voltage test at a motor between winding and housing, single windings or temperature sensor.

Adjustment of the „neutral zone″.

"Neutrale-zone"-adjustment at DC motors. For this, the brush rocker is turned until the neutral zone is exactly determined. The MotorAnalyzer shows the deviation direction-dependent, so that the operator immediately recognizes, in which direction the brush has to be turned.

top

top